KUKA brings a revolutionary controller to the automation

sport with the manage system of the destiny, the KR C4. The KR C4 is an

effective, clever, secure, and extra bendy controller which can carry a

scalable software capacity and extra in your manufacturing line.

It is absolutely

a pioneer for the automation enterprise because it has seamlessly incorporated

robotic and movement manipulate with manipulate strategies for %, CNC, and

protection.

The KUKA KR C4 also brings fee discounts in integration,

renovation and servicing, even as also increasing lengthy-term efficiency and

flexibility of the structures through all of the following advantages.

FLEXIBLE MANIPULATE:

The KUKA KR C4 is the uniform controller for all KUKA robots

starting from the low to high payload category. It is open structure permits it

to manipulate KUKA robots and external axes.

Via taking benefit of

cutting-edge, open technology together with Gigabit Ethernet and multi-middle

structure, KUKA Robotics has created a robotic controller that is compact, low

priced, and sturdy.

Even the software is established in a different way - with

all the additives sharing a database and infrastructure. KUKA brings to the

desk its newly evolved, floor-breaking, simply-dependent machine architecture

that creates open and powerful facts standards.

This lets in all integrated

controllers – from safety control, robot control, and motion control to logic

control – to have a joint database and infrastructure to apply and share

intelligently.

STRENGTH SAVINGS:

The new power management machine reduces power intake of the

controller to be decreased up to 95% in standby mode.

POWERFUL LAYOUT:

KUKA selected long lasting additives and a properly-designed

cabinet to help guarantee a dependable operation even underneath severe

situations. Protection, robot, logic, and motion control are all blended in a single

controller.

Secure records exchange measured in milliseconds bureaucracy the

idea for brand spanking new safety ideas in human system cooperation. It

understands its very own robot language KRL and also CNC and percent, enabling

it to communicate directly on your Siemens or Rockwell controller.

Additionally,

the database and infrastructure are shared, enabling a less complicated and

extra effective automation product. KUKA has finished an exceptional activity

with developing a advanced product with the KR C4-primarily based automation

solutions, supplying easy and bendy robotic programming thru inline bureaucracy

and new Spline motion programming.

BETTER PERFORMANCE:

The KR C4 has a high run-time overall performance and a

excessive-quit smooth % choice that allows full access to the whole controller

I/O gadget. This enables the I/O dealing with of the robotic, a whole robotic

cell, or even a line of more than one robot. Moreover, variables along with

axis positions and/or velocities can be study and processed through

characteristic blocks. The overall performance advantages don't stop there.

The

KUKA CNC manipulate alternative affords for the potential of direct programming

and operation of KUKA robots via G-code. This helps method complex packages

from CAD/CAM systems whilst offering a high degree of accuracy. All of this

technology coordination helps to simplify the integration of robots into a

current CNC environment.

IMPROVED PROTECTION:

The safety controller is integrated into the manage machine

with none proprietary hardware. Communication of the safety functions are

carried out through Ethernet-primarily based protocols whilst also allowing the

dual-channel operation required for safety packages, all the usage of

multi-center era.

VERSATILE AND DEPENDABLE:

The KUKA KR C4 controller can work with unique mains

voltages and types, and in intense environments together with bloodless,

warmness, or humidity. It also speaks 25 languages and meets all globally

applicable ISO and US requirements.

KR C4 VERSIONS:

All 5 versions of the KR C4 are advanced in every form. They

provide the patron with distinctive options for foremost integration into

particular automation surroundings. All of the one of kind varieties of the KR

C4 controller allow all requirements, together with stack ability, protection

against dirt, humidity and different impacts, to be taken under consideration.

The four different variations are indexed under:

KUKA KR C4 Compact: length: 271 x 483 x 460 mm protection

score

KUKA KR C4 Smallsize-2: size: 615 x 580 x 540 mm protection

score: IP fifty four size: 1160 x 792 x 558 mm protection score: IP fifty four

a hundred and sixty extended length: 1600 x 842 x 562 mm protection rating: IP 54

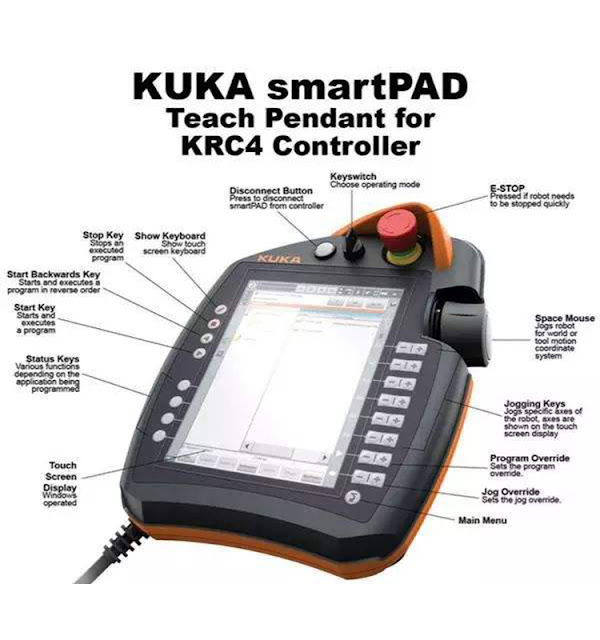

KUKA SMART PAD TRAIN PENDANT

The KUKA clever Pad train Pendant can perform all KUKA

robots and KR C4 controllers. It makes operating robots simple as it has easy operator

controllers with jog keys and six-D mouse. It features nicely -lit 8.4 display

screen with an intuitive consumer interface and user pleasant layout.

It has a

low weight for extra consolation and permits direct saving and loading

configurations thru the USB port. A 6D mouse and on board USB port offer new

ways to have interaction with a train pendant. The smart pad also includes keys

and a huge touch display.

It if the teaches pendant isn't always getting used; it is

able to virtually be unplugged all through on going operation. The portfolio of

KUKA software answers covers almost all utility to help meet almost each

customer requirement.

No comments:

Post a Comment